Measuring and changing locking cylinders

This text is machine translated.

Published: 16.11.2020 | Reading time: 10 Minuten

A properly locked office door or apartment door gives a good feeling of maximum security. After all, only the person who has the right key can open the door. Valuables and important documents are therefore securely protected against unauthorized access.

This is why it always makes sense to change the door locking cylinders when handing over an office or apartment. After all, you can never know exactly how many keys exist for the lock currently in use and who else has a key. Not to mention counterfeit and undocumented keys.

We will show you that measuring and replacing a door locking cylinder is quite simple in principle and that you don't need to call in a specialist. We also reveal other important information about locking cylinders and security.

A door lock cylinder or mortise lock is the part of a door lock that holds the key and enables a locking process with a suitable key. If access authorizations are changed, it is no longer necessary to change the entire door lock. It is sufficient to simply change the locking cylinder, or rather the profile locking cylinder. This is all the easier as the shape of the profile locking cylinder is always the same, despite different manufacturers.

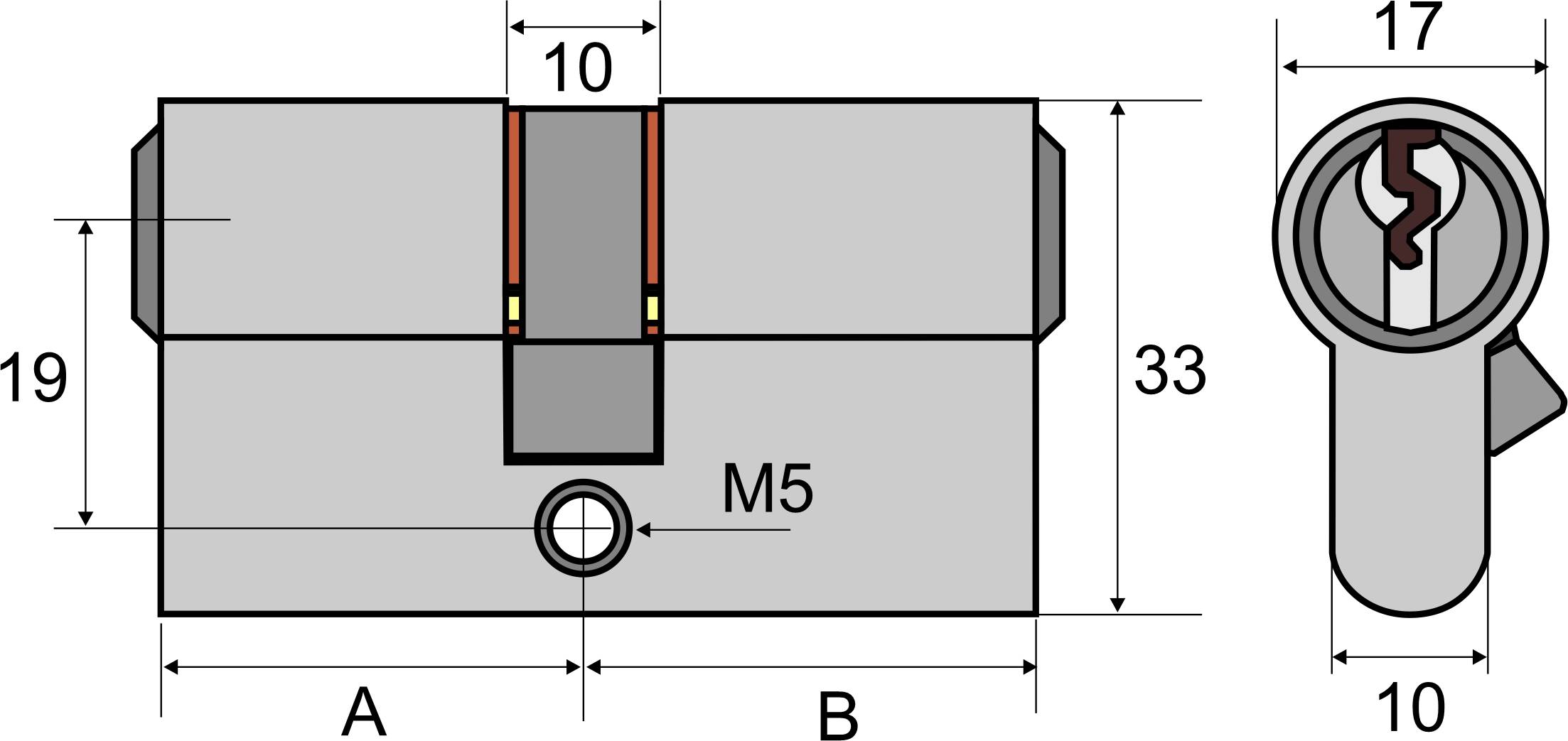

However, only the cross-section of the profile locking cylinder and the M5 thread for the fixing screw are standardized. However, the cylinders are available in different lengths. This is necessary as there are also a wide variety of doors.

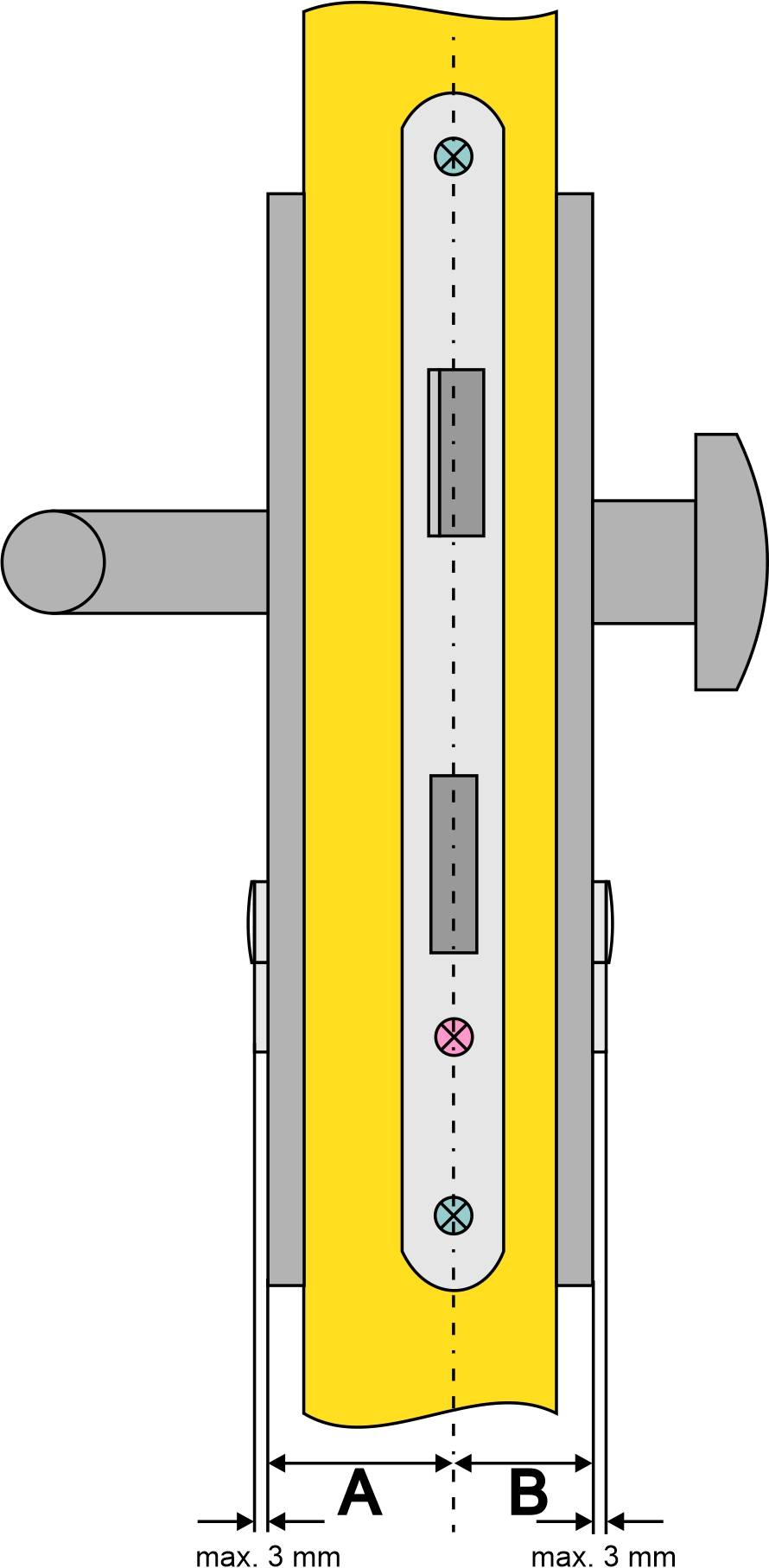

A large, heavy entrance door has a thicker door leaf than an intermediate door in the interior. But the mortise lock is also not always centered in the door leaf. As a result, the locking cylinders must be of different lengths despite having the same cross-section. The values for dimensions A and B can vary greatly depending on the installation requirements.

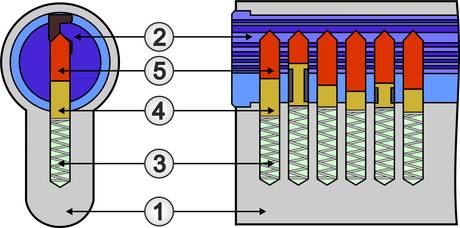

A profile locking cylinder, or simply door cylinder, consists of the cylinder housing and the cylinder core. The cylinder core is a metal cylinder that can rotate in the cylinder housing and holds the key in the key channel. There are vertical holes underneath the cylinder core, in which a pin spring, a housing pin and a core pin are housed.

The spring presses the housing pin and the core pin above it upwards against a groove in the key channel. As the pins have different lengths, the separation points of all pins or tumblers are not in the same plane or on the same line. The housing pins therefore protrude into the cylinder housing and the cylinder core at the same time. As a result, the cylinder core cannot be turned unless a suitable key is inserted into the lock.

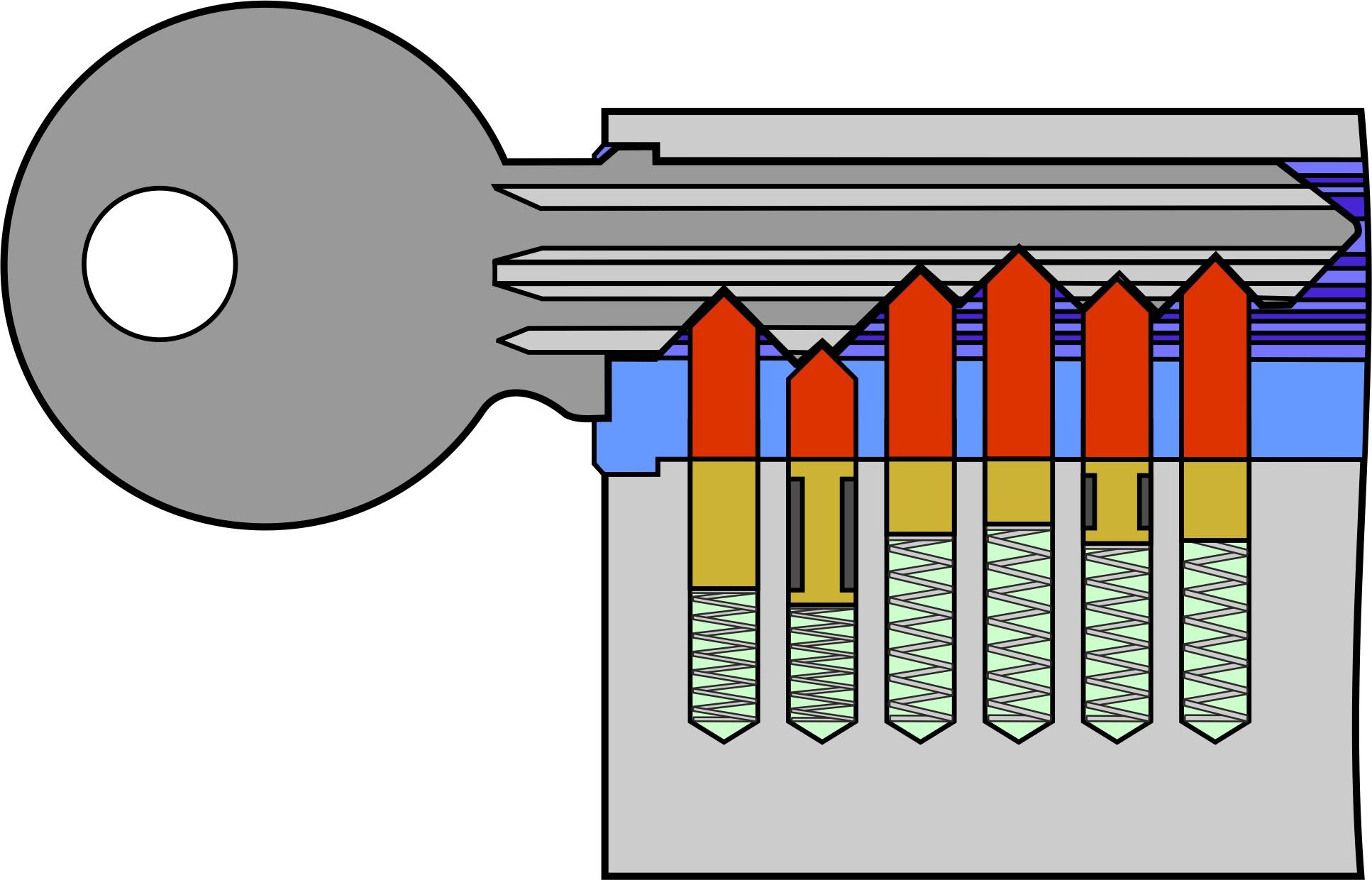

When a key is inserted into the key slot, the cylindrical pins (core pin and housing pin) are pressed downwards by the angled prongs in the key. The pin springs then press the cylinder pins back into the notches of the key profile.

When the key is fully inserted, the cylinder pins virtually feel the profile of the key. If the key and the lock belong together, the separation points of the housing pins and the core pins are exactly in line. And this line is then exactly between the cylinder core and the cylinder housing.

The cylinder core can now be easily turned with the key. As the separating points of the core pins are now in contact with the inner wall of the cylinder bore, the core pins can no longer move. The key can therefore no longer be removed at this point.

The closing beard

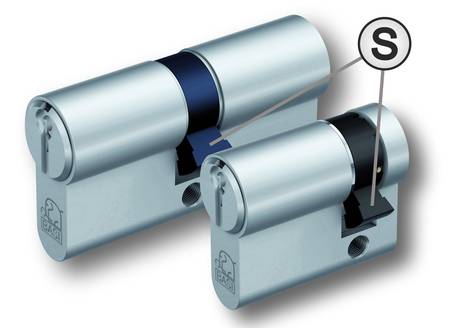

The cylinder core takes the lock bit (S) with it via a clutch. This then actuates the door catch (latch) or the locking bolt in the mortise lock, depending on the direction of rotation and current position.

When the key is vertical again and the core pins are positioned exactly above the housing pins, the key can be removed.

With a double locking cylinder, a key can be inserted from both sides and the locking system can be operated. With a half cylinder, the door can only be locked or unlocked from one side.

Reversible key instead of notched key

In contrast to the door cylinder with notched key described above, there are also high-quality locking cylinders with reversible keys. Notched keys can only be inserted into the lock in a certain position. Reversible keys have recessed holes and can also be inserted into the lock rotated by 180°.

Even though cylinders for reversible keys have up to 16 tumblers, they work in the same way as a cylinder with a notched key. Only the position of the cylinder core in which the key is inserted is rotated by 90°. The fact that a reversible key system offers greater security is still controversial and has not been proven beyond doubt.

Before a new profile locking cylinder can be selected, it is necessary to measure exactly how long the new door cylinder needs to be. As the mortise lock is not always centered in the door leaf, it may be necessary for the lock bit not to be centered in the profile locking cylinder either.

For this reason, the internal cylinder length (A) and the external cylinder length (B) are always specified for profile locking cylinders. The values always refer to the center of the lock bit, where the threaded hole of the fixing screw is located, and the respective outer edge of the door cylinder.

To measure the cylinder values for an existing lock, it is not necessary to remove the profile cylinder. Simply place a ruler, a wooden strip or another straight object against the door fitting and then measure the distance to the center of the fixing screw using a folding rule. This measuring process is carried out on the outside and inside of the door and the values A and B are determined.

As the cylinder lengths are graduated in 5 mm increments, take the measurement at which the profile cylinder protrudes the least from the door fitting. The profile cylinder should not protrude more than a maximum of 3 mm.

If the locking cylinder protrudes further, it provides too much of a target for burglars to break out by force.

When the door lock needs to be changed, most people don't mean the locking mechanism or the door latch or catch. Rather, they mean the locking cylinder or the cylinder lock with the keys. The rest of the locking mechanism can remain unchanged in the door, which makes it much easier to replace. The work is usually done quickly if you have a suitable screwdriver and the right key to hand.

Expansion

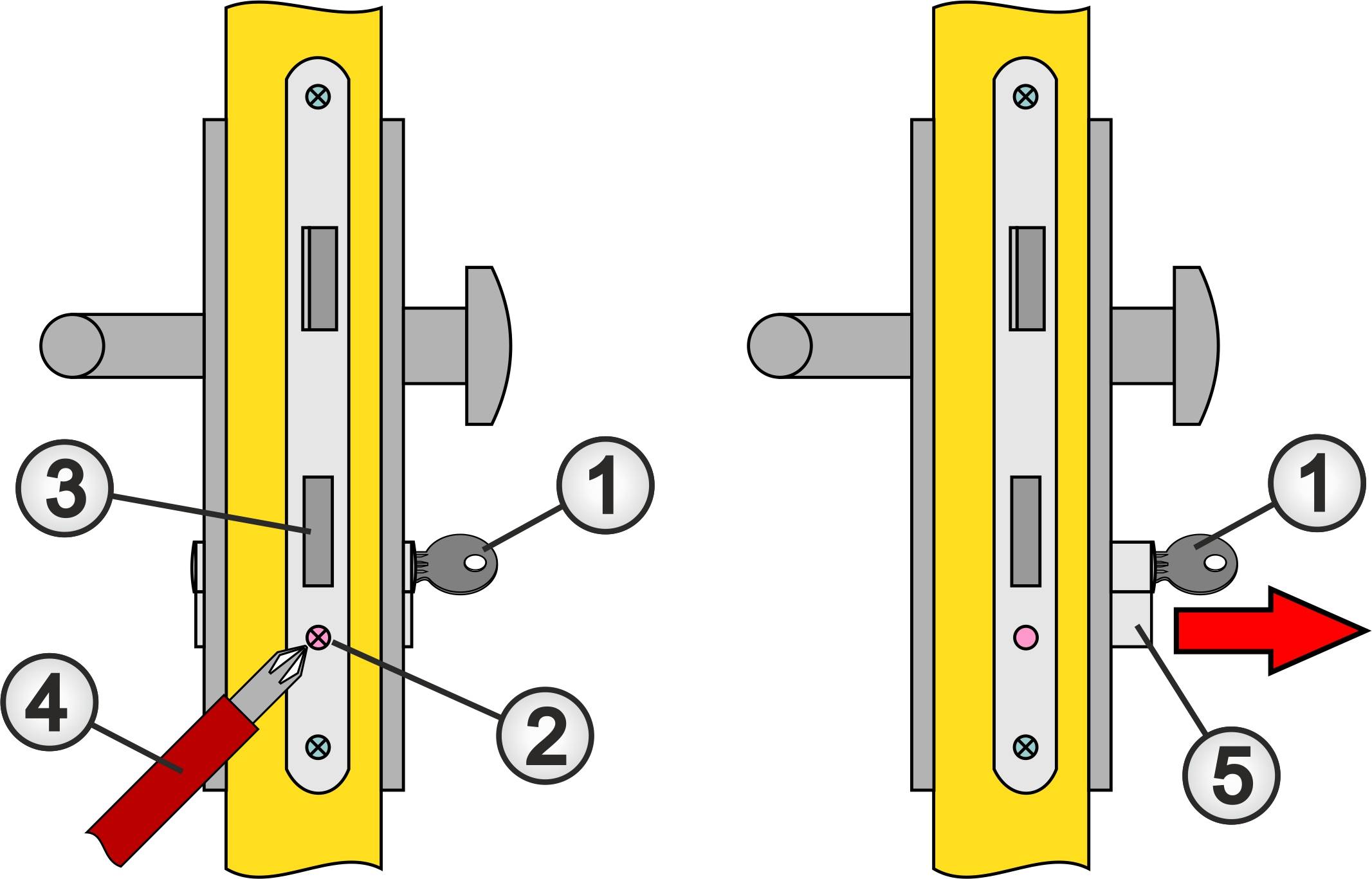

First insert the key (1) on the outside of the door and turn it approx. 30° to the right (13:00 position). This aligns the lock bit with the lock cylinder housing and it no longer protrudes to the side. In this position, the key is held securely in the cylinder core by the core pins.

The retaining screw (2) of the profile cylinder is then removed with the door open. The screw is located underneath the locking bolt (3) and engages in the lower area of the profile locking cylinder. Use a suitably sized screwdriver (4) so that the screw drive is not damaged.

Once the screw has been removed, the key can be pulled to remove the door cylinder (5). If it gets stuck, it helps to turn the key slightly so that the lock bit is aligned flush. If necessary, gentle counter-pressure on the inside of the door cylinder can also help.

Installation

To insert the new cylinder lock, insert the corresponding key on the outside and turn it until the lock bit is flush with the lock cylinder housing. Now push the locking cylinder from the outside of the door into the opening of the door fitting.

When the locking cylinder has been pushed in completely, you can turn the key to check whether the door catch (latch) and the locking bolt can be operated mechanically smoothly and without catching. Then screw in the retaining screw and tighten the screw sensitively.

After attaching the door cylinder, test the mechanical locking functions again with the door open. If everything works smoothly, the closing and opening functions can also be checked with the door closed. In the case of a double cylinder, the functions on both sides must be tested.

Important:

When inserting the new locking cylinder, pay attention to the internal and external dimensions if the internal cylinder length and the external cylinder length are different. Some profile locking cylinders have anti-drill protection. The locking cylinder must then be inserted so that the anti-drill protection is on the outside of the entrance door.

When converting to locking systems or when using a security door fitting, it may be necessary to convert doors with round locking cylinders to profile locking cylinders. Installation is generally possible, but requires a little manual skill.

First, the round cylinder must be removed. To do this, insert the key on the inside of the round cylinder and turn it 90° to the left.

The inside is easily recognizable by the larger core diameter. Then insert a 1.5 mm steel wire at the top edge of the key at an angle into the existing hole to release the locking mechanism of the two cylinder halves. The two cylinder halves can then be pulled apart and removed.

If required, there are some well-made videos on the Internet that clearly show the process.

Once the door handles have been removed, the old door fittings and the mortise lock can be removed. It may now be necessary to rework the openings in the door leaf, as the profile cylinder and possibly also the new mortise lock require more space.

Once this is done, the mortise lock is fitted in the door leaf. The new door fittings and the old door handles can then be screwed on. The profile cylinder can then be inserted and screwed in place.

The locking functions of the door must then be thoroughly checked.

What are keyed alike and keyed different cylinders?

With keyed alike profile cylinders, several locks can be opened or closed with one key. With keyed alike cylinders, only one lock can be opened or closed with one key.

What does emergency & danger function mean?

On profile cylinders with this function, the lock can be opened from the outside with a second key, even if the first key is still in the lock on the inside and has been turned so that it cannot be removed. With a profile cylinder without this function, you can insert a key into the lock on the outside, but not far enough to be able to turn it.

What is the difference between half cylinders and knob cylinders?

With a half cylinder, the door can only be locked and unlocked from one side. On the other side, the door lock cylinder is covered by the fitting. A knob cylinder, on the other hand, is a profile double cylinder that is operated on one side with a key and on the other side with a permanently mounted knob. Half cylinders as well as knob cylinders are available with notched or reversible keys.

What does anti-drill protection mean?

A locking cylinder with anti-drill protection has hardened steel rods incorporated at the front. The hardened steel pins are designed to prevent the cylinder housing from being drilled out underneath the cylinder core with a drill, thus disabling the spring mechanism with the housing pins and the core pins.

What lockpicking means

Lockpicking is the non-destructive opening of locks without the corresponding key. Special tools are inserted into the key channel and attempts are made to open the lock. Lock manufacturers try to make lock picking more difficult by using differently shaped housing pins and installing additional rocker arms and locking pins to lock the cylinder core.

What is a key card required for?

A key card or security card offers a high level of security. This is because additional keys can only be made after the security card has been presented. This effectively prevents the unauthorized duplication of keys.

What are locking systems?

Locking systems have a large number of locks and keys that lock in the same way. However, the keys and locks are related to each other in different ways and not all keys are keyed alike to the same extent. There are subtle differences.

Central locking system: The easiest way to see the central locking system is to look at a small table showing which key can be used to open which lock.

| Lock | Central key | Caretaker | Tenant 1 | Tenant 2 | Tenant 3 |

|---|---|---|---|---|---|

| Garage door | X | X | X | X | X |

| Front door | X | X | X | X | X |

| Apartment 1 | X | X | |||

| Apartment 2 | X | X | |||

| Apartment 3 | X | X |

System or master key system:

With this type of locking system, there is also a master key that can lock all the locks of a company. However, it is not necessary for the holder of an office key, for example, to be able to use it to open the gate at the company entrance.

Master key system:

In a master key system, there are individual keys that can only lock one lock at a time. Then there are group keys that can lock several individual locks. The master group keys in turn can take over the locking functions of several group keys. The master key can then lock all locks in the locking system.

The big advantage with even complex locking systems is the fact that several locks can be opened with one key. This saves the time-consuming search for the right key in each case and provides a decisive time advantage in dangerous situations. However, the loss of a central, master or master key can have serious consequences. In extreme cases, this can go as far as replacing all the locks.