Guide

This text is machine translated.

Useful information about temperature measurement technology

Temperature measurement technology includes a wide range of measuring devices, from simple room thermometers to complex thermal imaging cameras, which can be used to measure the temperature of objects, bodies or surfaces. Please read our guide to find out how the devices work and for which application areas they are suitable.

Temperature and temperature measurement technology

Devices and aids for measuring the temperature

Our practical tip: Measure the temperature of surfaces correctly

Temperature Measurement Purchasing Criteria – What's it all about?

FAQ – Frequently asked questions about temperature measurement technology

Temperature and temperature measurement technology

Measurement technology is a collective term for devices, processes and methods that are used to acquire physical variables. Temperature measurement technology is used to determine the thermal state of a body. In purely physical terms, temperature refers to the amount of energy inherent in a body. It is caused by the disordered movement of its atoms or molecules. If all particles are in rest, one speaks of the absolute zero point, which is indicated with 0 Kelvin (-273.15 °C). The temperature cannot drop below this point. According to the laws of quantum mechanics, there may not be a state of complete motion-free, but the zero point marks the origin of the absolute or thermodynamic temperature scale.

The beginnings of temperature measurement technology basically go back to ancient times. In ancient Greece, it was already known that air expands as the temperature rises and contracts again when it cools down. Building on this knowledge, Greek inventor Philon of Byzantium 200 B.C. developed a simple device for displaying temperature changes: The so-called thermoscope. It is considered a precursor of the thermometer and was essentially constructed like a barometer. This was also the disadvantage of the apparatus, because it was based solely on air expansion. In addition, it was not possible to determine specific measured values with this. With thermoscopes today's temperature measuring instruments have hardly anything in common. They allow very precise measurements and are sometimes highly complex.

Devices and aids for measuring the temperature

Temperature measuring devices enable the temperature of surfaces, solids, liquids and other media to be recorded quickly and comfortably. Electronic measuring devices are usually equipped with temperature sensors and easy-to-read displays. Occasionally, they have memory functions that prove useful when measuring series or when permanently recording temperatures. Temperature measuring instruments are available in many different versions, are used in private households as well as in industrial applications and are structured differently depending on the application area.

For example, penetration and food thermometers are specifically designed to measure the core temperature of foods. For this purpose, they are equipped with a insertion probe which is inserted into the object to be measured. These can be liquids, air and gases, but also semi-liquid and tougher masses such as meat, dairy products or dough.

Infrared thermometers and pyrometers are the means of choice for non-contact temperature measurement. They measure heat or infrared radiation emitted by every body whose temperature is above absolute zero. Infrared radiation is electromagnetic radiation, which is detected by a sensor integrated in the thermometer, converted into an electrical signal and finally processed further. Infrared thermometers and pyrometers enable reliable surface temperature measurement and can also be used from a distance to the object to be measured. In workshops or as part of construction work, the measuring instruments provide good service.

Infrared radiation is also detected by thermal imagers, which are available as individual devices or can be integrated into infrared thermometers. As the name suggests, thermal imagers map the temperature distribution of a surface. The imaging process is referred to as thermography in technical terms. Lower temperatures are shown in blue and violet, high temperatures in red to white. Thermal imagers offer the advantage of being able to examine objects even further away, and are suitable for locating thermal bridges in buildings or identifying weak spots in heating systems, for example.

Temperature measuring strips are an alternative to complex temperature measuring devices. These are usually adhesive films, which are permanently attached in one place and are therefore suitable for permanent temperature monitoring. Temperature measuring strips are equipped with heat-sensitive substances (indicators) that change their color as soon as a certain temperature is reached. Often, temperature measuring strips are additionally provided with a number scaling and thus provide concrete measured values.

In many cases, temperature sensors form the basis for a precise recording of the temperature. These are electronic components, which are often part of temperature measuring devices. Depending on the application, a distinction is made, for example, between air sensors, surface sensors and immersion sensors. Temperature sensors are sensors that can be constructed in different ways. So-called NTC thermistors (NTC = negative temperature coefficient) reduce their resistance as the temperature increases. For PTC thermistors or PTC thermistors (PTC = positive temperature coefficient), the resistance increases with the temperature. All temperature sensors share the common fact that they convert the recorded temperature into an electrical signal and thus make it measurable. With the help of temperature sensor accessories such as adapters, cables and plug sets, the sensors can be replaced or aligned to the measuring device according to your own requirements.

Our practical tip: Measure the temperature of surfaces correctly

If a temperature measuring device is equipped with a sensor, it is important to place the same as vertically on the measuring surface as possible. The area to be measured should also be level. If the sensor is placed at an angle or if the surface is uneven, the measurement results may be incorrect. In a non-contact temperature measurement, however, it is important that the surface is free of disturbances such as dust, dirt, moisture and the like, since the top layer is always measured.

Temperature Measurement Purchasing Criteria – What's it all about?

An essential criterion when purchasing temperature measurement technology is the application purpose. If the temperature of hard-to-reach places or moving objects is to be detected, the handle for infrared thermometers or pyrometers is recommended, which enable contact-free temperature measurement. For the measurement of the core temperature of liquids and foodstuffs, contact temperature measurement is recommended. The reason for this is that thermometers that measure contact-free only always record the surface temperature. In addition, contact temperature measurement on smooth, thermally conductive surfaces offers higher accuracy than non-contact measurement. Measuring instruments with a set of different temperature sensors that can be changed are suitable for several application areas and thus can be used flexibly.

In addition, the measuring range (minimum and maximum temperature) and the measuring accuracy are important factors when selecting a suitable measuring device. Both should be chosen wisely. For example, a measurement range between -50 and +5000 °C is not necessary for standard household measurements, while temperature measurement technology, which does not provide precise measurements, is not a good basis for professional analyzes. The measurement rate indicates the frequency at which a temperature sensor measures and can also play an important role in the accuracy of a measurement. In addition, the type of calibration (DAkkS, ISO) and the IP degree of protection must be taken into account, especially when it is expected that the thermometer or measuring device will come into contact with dust or water.

Equipment and functions of a measuring instrument should meet the requirements of the measurement and the application area. Measuring devices with integrated data loggers for storing measurements are extremely helpful for performing temperature observations and analyzes. Via an interface (SD card, microUSB, WLAN etc.) the data can be transferred to the PC and finally evaluated. A good display resolution and LED lighting offer operating comfort, which should not be ignored especially with regular temperature measurements.

FAQ – Frequently asked questions about temperature measurement technology

What was the term calibration?

Over time, the measurement accuracy of thermometers may decrease. This can be attributed to external influences (corrosion, mechanical damage, excessive temperatures) and to aging and wear of the measuring technology itself (wear of the material). A calibration can be used to determine whether there is a difference between the measured and the correct value and how high it is. In the professional field, regular calibration of measuring technology is important in order to obtain reliable values.

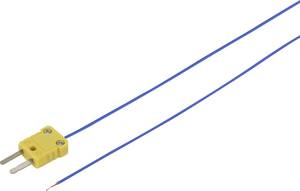

What was thermo element?

Thermocouples are sensors. They consist of two wires of different material, which are linked together on one side and coupled to a measuring device on the other side. If the connection point has a different temperature than the opposite side, a voltage is generated which can be measured using the measuring device and converted into a temperature value. Thermocouples therefore always measure the temperature difference.