LED » The light-emitting diode briefly explained

Updated 25.05.2022 | Reading time: 9 minutes

This text is machine translated.

The three letters LED stand for Light Emitting Diode, which means light emitting diode. Originally, LEDs or light-emitting diodes were used as optical LED displays in devices or circuits and were only available in the colors red, green and yellow. However, blue and white LEDs are now also available. In addition, the luminosity of LEDs has been increased to such an extent that LEDs function as efficient light sources, for example in LED spotlights or flashlights. This is why we encounter LEDs everywhere: whether in traffic lights, displays or in modern LED lighting for private and business premises. Thanks to their long service life, small size and wide variety of shapes and color spectra, LED lamps have quickly replaced incandescent bulbs, halogen and energy-saving lamps. But behind every LED is a whole piece of clever technology, which we would like to explain to you below.

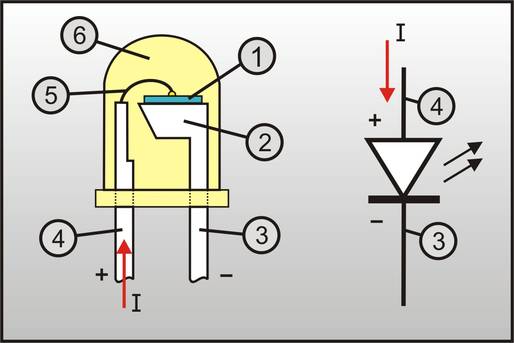

An LED is one of the semiconductor components in the III/V semiconductor group. This means that it consists of materials that belong to the third and fifth groups in the periodic table. The semiconductor materials used form a diode that only allows current (I) to flow in one direction. In an LED, the current flows from the anode towards the LED chip. The core of an LED is the semiconductor crystal, which sits in a reflector well.

The structure of a light-emitting diode can be easily explained using the example of a wired LED.

(1) The semiconductor crystal (also known as the LED chip) is the heart of the LED and generates light by means of physical processes.

(2) The reflector well, in which the LED chip is installed, increases both efficiency and luminous efficacy.

(3) The cathode (-) is connected to the reflector well.

(4) Current flows via the anode (+) in the direction of the semiconductor crystal.

(5) A thin wire (bond wire) connects the LED chip to the anode.

(6) A plastic lens surrounds the structure and influences the radiation angle and light output. Depending on the intended use, it is oval, triangular, curved or flattened.

The switching symbol (figure on the right) illustrates the current flow from anode to cathode and the resulting light waves (arrows). For an LED to function in a circuit, it must be installed with the correct polarity. To ensure that the LED is inserted correctly, the connecting wire of the anode is usually slightly longer.

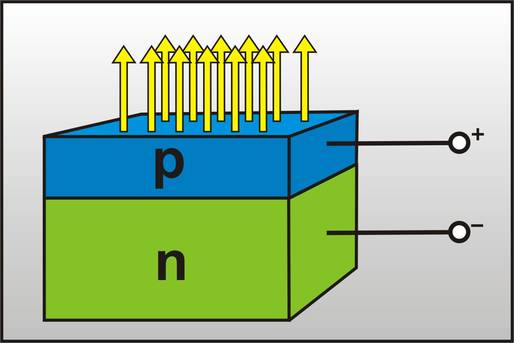

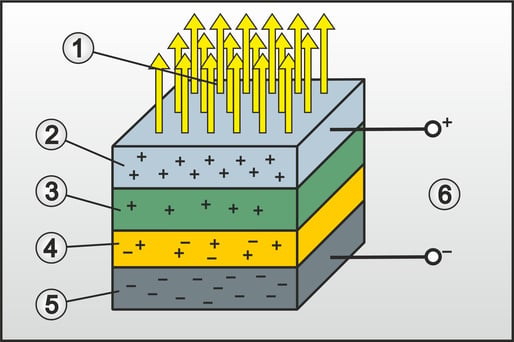

Structure of the LED chip:

Green is the negatively doped layer of a semiconductor material (n-layer).

Blue is the positively doped layer of a semiconductor material (p-layer).

Light waves emerge from the p-layer.

By the way: During doping, the semiconductor crystal is deliberately "contaminated" with foreign atoms in order to change its conductivity. This leads to an excess of electrons in the p-layer and a lack of electrons (electron holes) in the n-layer. This is the basis for the processes that lead to light generation.

As already shown, there are two layers of semiconductor materials on the semiconductor crystal. An n-doped layer has an excess of electrons, while a second, thinner p-doped layer has too many defect electrons, also known as electron holes. If a voltage is applied across the two layers in the direction of flow of the LED, the excess electrons migrate towards the p-layer. They meet the electron holes in the so-called barrier layer. There, the electrons that have migrated and the electron holes begin to recombine. This means that both charge carriers unite. Recombination is therefore the reverse process of ionization.

In contrast to ionization, which requires energy, recombination releases energy that is emitted in the form of light flashes (photons) via the thin p-layer. The LED chip transmits these flashes of light to the outside, with the inside of the reflector trough amplifying the emitted light. This process continues as long as free electrons are supplied via the voltage source. In addition to the flashes of light, a small amount of waste heat is also generated during recombination.

The following video explains how a light-emitting diode works very clearly:

The light color of the LED light-emitting diode depends on the doping of the layers and the semiconductor materials used. These different combinations have different energy levels. During the recombination of the electrons, photons with different energy levels are released. These determine the color of the light or the wavelength of the visible light.

For example, short-wave blue light is produced at a high energy level and long-wave red light at a low energy level. There are now numerous suitable material systems so that light-emitting diodes can reproduce almost all colors monochromatically (single color).

The following substances are often used to create the corresponding colors:

- Aluminum gallium arsenide (AlGaAs): Red with a wavelength of 650 - 750 nm

- Gallium arsenide phosphide (GaAsP): Yellow with a wavelength of 575 - 585 nm

- Gallium phosphide (GaP): Green with a wavelength of 490 - 575 nm

- Indium gallium nitride (InGaN): Blue with 420 - 490 nm wavelength

In addition to the colors shown, such as red, green, yellow or blue, there are also LEDs that work with invisible infrared light. These IR LEDs can be found in the remote controls of televisions, DVD players or SAT receivers. But there are also LEDs at the other end of the visible range that operate in the UV range. IR and UV LEDs are also sometimes used in light barriers to minimize interference from visible light.

Our practical tip: Check IR remote controls

If the TV remote control is not working despite having new batteries, you can easily check whether the IR LED on the remote control is emitting light signals. All you have to do is press a button on the remote control and look at the IR LED. However, as the human eye cannot recognize infrared light signals, the camera of a smartphone is also used. As a rule, cameras do not only work with light in the visible frequency range. In some cases, the cameras can also detect light in the IR range, making the light signals from the IR LED clearly visible on the smartphone display. For test purposes, a functioning remote control can simply be scanned with the smartphone camera.

Creation of white LED light

For lighting purposes in particular, it is necessary to produce white light. Two different processes are used to achieve this goal:

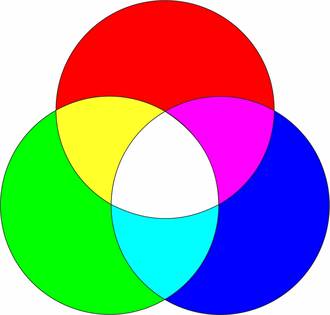

Additive color mixing

Just as a prism splits white light into its different spectral colors, this process can also be used in reverse. Different colored LEDs are combined for this purpose. White light is created by superimposing the three primary colors red, blue and green. The colors red and green produce yellow, red and blue become magenta and green and blue produce cyan.

A multicolor light-emitting diode therefore contains three semiconductor crystals, each of which produces one of the three primary colors. These LEDs are also known as RGB LEDs. RGB LEDs can be found in LED strips with a color-changing function. This is because a seemingly limitless variety of colors can be created by using primary colors with different intensities.

Luminescence

A blue light-emitting diode is coated on the inside with a thin layer of phosphor. Some of the high-energy blue light waves excite the phosphor to glow, causing lower-energy yellow light to be emitted. The mixture of yellow and blue light produces a light that is white to the human eye.

Structure of an LED chip with luminescence technology:

The combination with the blue light waves results in a yellowish or bluish light that appears warmer or colder. The "colorfulness" of white light is specified as the color temperature in Kelvin.

In some cases, RGB LEDs are supplemented with white LEDs to create RGBW LEDs in order to produce optimal white light in addition to colored light.

As they can be used in many areas, different LED designs are required. Wired LEDs, SMD LEDs and COB LEDs are currently standard.

Wired LED

The wired light-emitting diode was the first design on the market and is easy for hobby technicians to solder. They can be found in electrical appliance switches, for example.

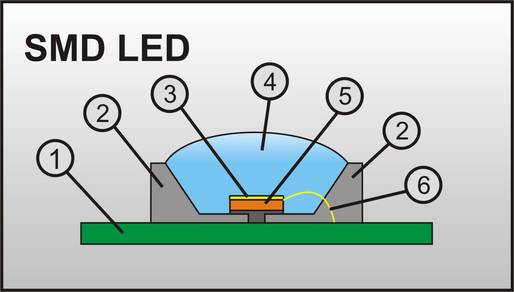

SMD-LED

SMD LEDs are often found in industry, but are now also used in private households. It gets its name SMD (surface mounted device) from the way it is attached, as it can be soldered onto a circuit board. Its design makes it flatter, smaller and therefore more versatile than a wired LED, for example. This is why LED strips are also equipped with SMD LEDs, as a large number of this design can be easily grouped together.

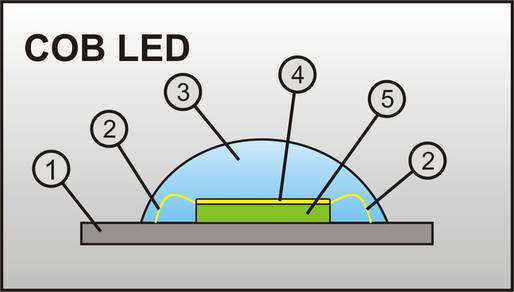

COB-LED

A third variant is the COB LED (Chip On Board), which is soldered directly onto circuit boards. One or two gold wires connect the chip connections to the circuit board. This LED is considered powerful and is suitable for tightly packed LED modules. These are found in LED tubes, for example. In contrast to wired LEDs and SMD LEDs, which are already encapsulated, a COB LED requires an epoxy lens to be bonded to the light-emitting diode. The advantage of this lens is that the beam angle of the light can be flexibly designed. In addition, the circuit board is also used for cooling. We recommend applying thermally conductive adhesive to the circuit board to secure the LED and dissipate the heat even better.

HighPower LED

Many LED manufacturers call some of their products high-power LEDs. Especially when it comes to generating very bright light in a small area, for example in flashlights or spotlights. However, it should be noted that there is no official definition of a high-power LED. This is why the lumen, watt and ampere specifications for this group vary greatly.

LEDs are not designed for high voltages. The voltage at which a diode must be operated also depends on the color:

- IR LEDs have an operating voltage of 1.2 - 1.8 V

- Red LEDs have an operating voltage of 1.6 - 2.2 V

- Green or yellow LEDs have an operating voltage of 1.9 - 2.5 V

- Blue or white LEDs have an operating voltage of 2.7 - 3.5 V

- UV LEDs have an operating voltage of 3.1 - 4.5 V

The exact voltage values as well as the current must be taken from the technical documentation of the diode.

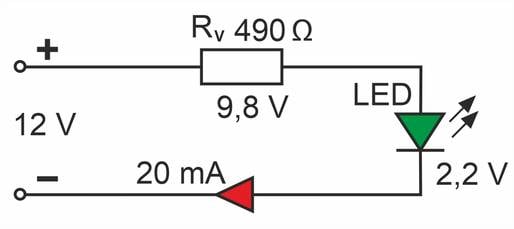

Calculate LED series resistor

If, for example, a wired standard LED is to be operated with 2.2 V and 20 mA at 12 V, both the voltage and the current must be limited with a series resistor.

The resistor should be designed so that a voltage of 9.8 V (12 V - 2.2 V) drops across it when a current of 20 mA flows. The resistance can be calculated according to Ohm's law R = U : I (9.8 V : 0.02 A = 490 Ω). Depending on the resistance series, a resistor with 510 Ω or 560 Ω is then used in practice.

Select ballast or LED driver

With super-bright high-power LEDs, on the other hand, the manufacturers specify the specific operating current as well as the voltage range. In this case, special LED drivers or ballasts must be used that supply exactly this current.

Important: The total power of all connected LEDs must not exceed the power of the ballast.

Particular attention must be paid to the temperature of an LED, especially if you want to install high-power LEDs, as LEDs are very sensitive to excessive heat development.

If a light-emitting diode no longer works, it is rarely due directly to a faulty semiconductor crystal. Instead, it is often due to excessive temperature development, which can be caused by excessive operating current or poor processing. The resulting heat destroys the complex construction inside the semiconductor crystal, for example.

This seems surprising. After all, anyone who touches an illuminated LED will feel very little heat development. This is due to the fact that LED technology produces little waste heat, as the light is generated by emitting photons. A light bulb generates a comparatively large amount of heat, as the light is produced by heating a material, and radiates this heat.

But even if it is hardly noticeable on the outside: Inside a light-emitting diode, the temperature rises because a small amount of heat is generated as a by-product. This happens, for example, if the current flow is too high as a result of a series resistor that is too small or an incorrect switching structure.

The cooler your environment is during operation, the better it is for an LED in terms of functionality and service life. An ambient temperature that is too warm can significantly shorten the life of the light source. Depending on the design, there are different means of cooling. As a rule, the heat is dissipated via another material such as aluminum or ceramic. The bases of LED light sources, for example, are made of one of these two materials. With SMD LEDs, the chip forms a single unit with the heat sink.

Advantages of light emitting diodes

Economic efficiency

Low energy consumption thanks to high efficiency, i.e. brighter lighting with lower power consumption. This can be recognized by the low wattage compared to conventional light bulbs.

Long service life: Depending on the semiconductor materials and operating conditions, an LED generally lasts between 15,000 and 50,000 hours.

If operated for 3 hours a day, this corresponds to a service life of 14 to 45 years.

Design

Small design, resulting in lower delivery costs, for example.

Great flexibility due to variety of shapes, for example they fit into conventional luminaires.

Due to the variety of types and colors as well as their dimmability, LEDs can be used in many different areas. Not only in luminaires, but also as backlighting for LC displays, as infrared LEDs in light barriers, in optoelectronics or in signaling systems.

Technology

Safety due to low voltage.

Shock and vibration resistant.

Low switch-on delay.

Hardly any downtime.

Virtually maintenance-free during the entire operating time.

Environmental compatibility

LEDs do not contain any toxic substances.

LEDs are therefore characterized by a very high level of environmental compatibility.

Disadvantages of light emitting diodes

Economic efficiency

Higher acquisition costs

Technology

When used in rooms where there is a lot of moisture, such as bathrooms or kitchens, components of the LED lights can corrode.

This can cause the LED to fail. Metal parts, connections and electronic components are particularly sensitive.

When purchasing, pay attention to the IP standard of the LED to avoid corrosion.

Environmental compatibility

Rare soils are necessary.

Disposal at waste collection points, not in household waste.

The light sources in many LED lights are permanently installed. This means that they must be disposed of completely as soon as the light source is defective.

The term OLED or organic light-emitting diode is often used in connection with displays or televisions. In principle, an organic LED works like a conventional LED, except that there is a structure of one or more organic films between the electrodes.

Structure of an OLED chip

In contrast to LCD displays, which inevitably require a backlight, displays with organic LEDs light up automatically. If the LEDs are not activated, they simply remain dark, allowing black areas in an image to be displayed perfectly. As there is no backlighting, there is also no annoying shimmer-through effect with the color black.