Industry 4.0 » Digital networking and transformation

In a world that is constantly evolving and changing, industry is facing a revolution like never before. Industry 4.0, also known as the fourth industrial revolution, is the key term that defines the future of the manufacturing and production industry. The development goes beyond pure automation and encompasses the complete digital networking and transformation of production processes. The following topics play an important role here:

Industry 4.0 is characterized by the integration of digital technologies into all aspects of industry, from plant construction to maintenance planning. The aim is to break down silos and network teams, smart devices and processes across the entire company and production landscape.

Artificial intelligence (AI) is at the heart of the fourth industrial revolution. Thanks to it, companies and manufacturers can not only collect the huge amounts of data from all over the world (big data) that are available today, but also use them. However, Industry 4.0 is not just a dedicated technology, but is characterized by a whole range of systems, tools and innovations - such as industrial IoT networks, augmented reality, cobots (collaborative robots), automation & robotics, or condition monitoring.

These enable companies to optimize their production processes and increase efficiency and flexibility, ultimately creating smart factories.

The basis: four principles of Industry 4.0

Thanks to the fusion of digital and physical technologies, Industry 4.0 is able to revolutionize the industrial sector - guided by four principles:

-

Connectivity:

In Industry 4.0, machines, systems, sensors and people are connected with each other and can exchange information seamlessly. This not only facilitates more precise and timely decision-making, but also leads to improved monitoring, control and optimization of production processes.

-

Information transparency:

Thanks to advances in sensor technology and data collection methods, companies now have access to vast amounts of operational and performance data. This data can be used to create a virtual replica of the physical world - a digital twin that enables a better understanding and more accurate modeling of processes.

-

Technical support:

When systems are equipped with artificial intelligence (AI) and machine learning, they are able to help people make well-informed decisions and solve complex problems. They can also take over potentially dangerous or unpleasant tasks for human workers.

-

Decentralized decisions:

Whereas previously only humans were able to make simple decisions independently, cyber-physical systems now also have this ability. This results in increased flexibility and faster reactions within production processes.

Technical pillars of the digital industrial transformation

Basically, Industry 4.0 can be said to be based on various important pillars that form the foundation for the digital transformation of the industrial landscape. Here are some of the most important ones:

Networking and digitalization

A key aspect of Industry 4.0 is that a wide variety of components within an industrial system are networked with each other and can communicate seamlessly. This networking - in conjunction with digitalization - enables comprehensive data collection in real time. This data can then be evaluated using advanced analytics and AI technologies to enable informed decisions.

On a horizontal level, this can be production processes that are connected across multiple production sites and across the entire supply chain. On the other hand, information can also flow vertically across all company levels, from production to the executive floor and back again. This reduces data and knowledge silos and streamlines processes.

Intelligent communication between machines and systems improves efficiency and ensures greater flexibility and responsiveness. Digitalization converts physical processes and information into digital data, enabling precise monitoring, analysis and optimization.

Big data and analytics

In Industry 4.0, extensive data is collected from various sources, including constructions, equipment and IoT-enabled devices. This data collection spans all aspects of manufacturing and beyond, including global business units.

The role of big data is to manage, store and process these vast amounts of data. This enables companies to gain valuable insights from the information, whether in terms of efficiency gains, quality improvements or innovative product developments. Analytics, especially AI-supported analyses and machine learning, play a central role in extracting relevant patterns, trends and forecasts in real time.

The insights gained from big data and analytics are used to make informed decisions and improve automation solutions in production and supply chain management. In this way, big data and analytics help to increase the efficiency, agility and innovative capacity of companies in Industry 4.0.

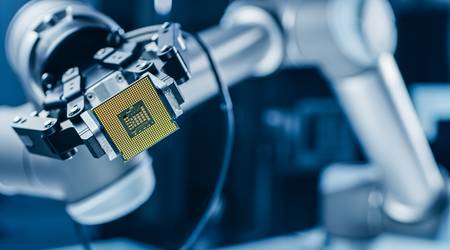

Automation and robotics

By automation, experts mean the machine execution of tasks that previously required a person. Automation allows repeatable and time-consuming tasks to be carried out precisely and efficiently. Robots can work continuously, without fatigue or error-proneness, leading to an overall increase in production output. Robotics, on the other hand, essentially describes the development process of robots of various functions and sizes. From drones for inventory monitoring to autonomous mobile robots that perform pick and place operations.

Industrial robots are often designed in such a way that they can react flexibly to different tasks. Through programming and adaptability, they can quickly adjust to changing production requirements. By networking and integrating data in real time, industrial robots can not only perform complex tasks autonomously, but can also be seamlessly integrated into intelligent production systems.

>> More information in our guide to robotics.

Cobots

Collaborative robots, also known as cobots, are designed to interact safely with humans. This form of robotics enables direct collaboration between humans and machines, which is particularly beneficial in environments with variable or complex tasks.

Cobots are also affordable for small and medium-sized businesses, allowing them to reap the benefits of automation without the fear of exploding costs. Their easy integration and adaptability lead to lower implementation costs and faster return on investment (ROI). Overall, cobots help to strengthen the agility and competitiveness of companies in Industry 4.0.

>> More information in our guide to cobots

Cyber-physical systems (CPS)

Cyber-physical systems (CPS) enable the seamless connection of physical and digital components.

An intelligent production cell, for example, consists of production machines and robots (physical), which are programmed accordingly and equipped with sensors and have access to a networked production database (digital). The various components of the cell are networked via the IIoT and can communicate with each other.

CPS enable precise monitoring and control of production systems. By integrating data analysis and artificial intelligence, processes can be optimized in real time to increase efficiency and productivity. They are also extremely flexible and can adapt quickly to changing requirements and product variants, which is an advantage in an increasingly individualized production environment.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to the integration of internet-enabled sensors, devices and systems into industrial processes. It emphasizes the networking of physical devices via the internet in order to collect and monitor real-time data. This involves connecting constructions, systems, data and software. In this way, a wide variety of data can be linked and evaluated to make production more efficient.

The IIoT can be considered a sub-area of CPS, as it is one of the technologies that can be integrated into the creation of cyber-physical systems. The IIoT is considered the basis for networking and interconnectivity in industry - and therefore a key factor in digital transformation.

Augmented Reality (AR)

Augmented reality usually overlays a real environment with digital content. With the help of special glasses or mobile devices, IIoT data can be visualized in real time.

For example, technicians can see repair or assembly instructions, diagrams or instructions directly on the physical devices. This makes maintenance and repair work easier, as relevant information is provided in real time.

Information about the manufacturing process can also be projected directly onto machines or production lines, making it easier to monitor production parameters and react immediately to deviations. Virtual training can be tailored directly to the individual employee's working environment and they receive instructions for complex tasks in real time.

AR is still in its infancy, but will have a major impact on maintenance, service and quality assurance, as well as on the training and safety of technical specialists.

Simulation / digital twins

Closely related to the topic of augmented reality (AR) is the simulation of a so-called digital twin. A digital twin is a virtual representation of a physical object (machine, product), system or process. It is created by continuously capturing and updating IIoT sensor data in real time.

This digital twin enables the real object or system to be mapped virtually and analyzed, monitored and simulated in the virtual world. AR is often used to project the information and analyses from the digital twin into the real world. For example, a plant operator can use a digital twin to identify a specific faulty part, predict potential problems, improve uptime and simulate different scenarios and conditions.

In addition to configuring and maintaining machines, a digital twin can also simplify collaboration between different teams. By visualizing processes, systems or products, discussions and planning can be carried out more effectively. This promotes a holistic and interdisciplinary approach in Industry 4.0.

IT security and data protection

The integration of digital technologies in Industry 4.0 offers impressive opportunities, but also poses new challenges. Extensive connectivity, a key strength of this revolution, presents a significant attack surface. Potential attackers, from individuals to government agencies, have increased exponentially in recent years and the exploitation of vulnerabilities in networked systems has become a serious threat. Therefore, effective cyber security is important in Industry 4.0.

A comprehensive strategy should include regular risk assessments, holistic risk management and critical network security measures such as firewalls and intrusion detection systems. Identity and access management, encryption of data transmissions and security awareness training are key aspects. Clear incident response plans, regular software updates, access control for IIoT devices and compliance with security standards and data protection laws form a robust line of defense against the growing cyber threats in Industry 4.0.