LFP batteries » Modern power storage with lithium iron phosphate

Published: 10.10.2023 | Reading Time: 4 minutes

This text is machine translated.

Lithium-ion rechargeable batteries, or batteries as they are now also known, are ideal for many mobile and stationary applications. This is because they have an enormous energy density, which enables a very compact design despite their high storage capacity. Our super-slim smartphones are the best proof of this.

However, the automotive industry is also increasingly relying on high-performance lithium batteries in a wide variety of designs, such as NMC cells or NCA cells, for electromobility .

Unfortunately, in addition to the many great advantages, there are also some disadvantages that we do not want to conceal. In the case of lithium batteries, these are expensive raw materials such as nickel, manganese or cobalt, some of which are mined and traded under very questionable circumstances.

Another critical point is thermal instability, which has already caused many a battery fire. In order to get a grip on these problems, rechargeable batteries with lithium iron phosphate (LFP) have been developed, which we would like to introduce to you here.

The lithium iron phosphate battery is also known as LEP or LFP, where LFP stands for lithium ferro phosphate(LiFePO4). Consequently, LFP batteries also belong to the large family of lithium batteries.

The positive electrode of the battery consists of lithium iron phosphate and does not contain nickel, chromium or manganese. The negative electrode of the battery is made of graphite, as is the case with other lithium batteries.

Lithium iron phosphate batteries are available in a cylindrical design , usually as 14500, 18650 or 26650 cells. However, manufacturers also offer flat pouch cells sealed in aluminum foil or prismatic cells with a solid housing (see cover picture).

Although the technology of lithium iron phosphate cells was already developed at the end of the 1990s, this technology has unfortunately not yet achieved a major breakthrough.

Due to the significant increase in the price of nickel, cobalt and manganese, LFP batteries are becoming increasingly attractive for the industry. Especially as the further technical development of LFP technology is helping batteries to achieve ever greater capacity.

Our product recommendations for LiFePO4 batteries

LiFePO4 batteries basically work on the same principle as all rechargeable lithium-ion cells.

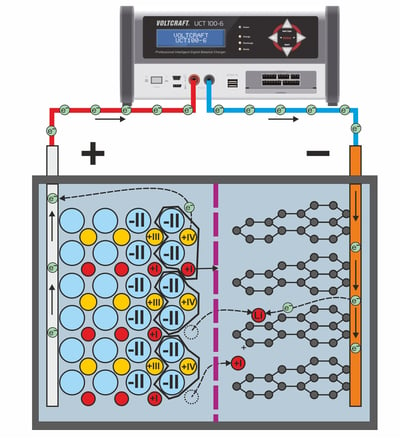

Charging process

The external charging voltage draws negatively charged electrons away from the positive terminal of the battery. As a result, positively charged lithium ions migrate internally from the positive electrode through the electrolyte and the separator to the negative electrode. There, the lithium ions absorb the electrons provided by the charger and are deposited in the graphite of the negative electrode.

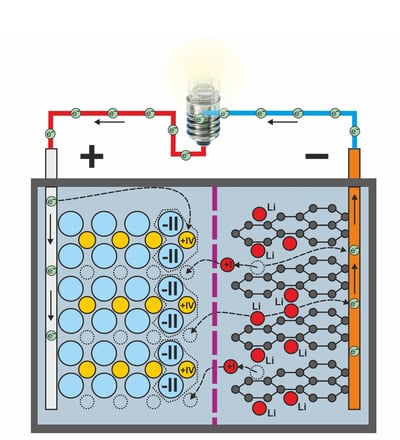

Discharging process

To discharge, a consumer is simply connected to the two terminals of the battery. The lithium at the negative electrode releases its electron and moves internally as a positively charged ion back to the positive electrode. There, the electrons that come via the circuit enable the positively charged lithium ions to be reinserted into the positive electrode.

A more detailed description of the processes involved in charging and discharging lithium batteries can be found in our guide to Li-ion technology.

Clever battery management systems (BMS), which are either installed in the respective device or even directly in the battery, ensure that the charging and discharging parameters are maintained correctly.

As already mentioned, LFP cells do not use expensive components such as nickel, manganese and cobalt. This primarily has a positive effect on the price. But not only that. As some of these raw materials are mined under highly questionable ecological and humanitarian conditions , doing without them is also commendable for ethical reasons. However, LFP cells also do not achieve the high energy densities of NMC/NCA batteries. We have listed an exact overview of the advantages and disadvantages below:

Advantages of LFP:

- No nickel, manganese and cobalt

- Inexpensive production

- High thermal safety

- High charging and discharging currents

- High cycle stability

- Long service life

- Flat discharge curve

- Wide temperature range

- Easy recycling

Disadvantages of LFP:

- Low energy density or specific capacity

- Intelligent BMS required*

*Sometimes an advantage can also be a disadvantage in lithium technology. On the one hand, the flat discharge curve ensures a long power output at a constant level; on the other hand, the current state of charge (SoC = State of Charge) cannot be detected by the battery management system(BMS) by means of a simple voltage measurement. In this respect, significantly greater effort is required for an efficient BMS.

Until now, the low energy density has been the knock-out criterion for this battery technology. At least for mobile applications. However, for stationary applications such as stationary energy storage for solar systems (BESS), it makes perfect sense to rely on LFP batteries. This is because the low energy density and the resulting reduced storage capacity can easily be compensated for by additional batteries. Weight and space requirements usually play a subordinate role in these applications.

Until now, the main area of application for LFP batteries or rechargeable batteries has mostly been where safety and longevity play a major role. At the same time, the increased space required for additional cells to increase capacity should not be an obstacle . Lithium iron phosphate cells were therefore used for stationary energy storage, in industry, construction, shipping and a wide variety of special vehicles. Due to their design, LFP batteries are also often used to replace lead-acid batteries or lead-gel batteries.

The further technical development of lithium iron phosphate batteries is also continuously increasing the usable capacity of lithium batteries.

The high level of safety with regard to thermal runaway (self-ignition), the enormous cycle stability and the high charging currents make this battery technology increasingly interesting for manufacturers of electric cars.

In addition to NMC and NCA batteries, car manufacturer Tesla is now using improved LFP batteries in the Model 3 and Model Y (in the basic version).

Perhaps e-mobility and the use of LFP technology in electric cars will be the big breakthrough after all.