NMC Battery & Rechargeable Battery " The Nickel-Manganese-Cobalt Technology

Published: 10.10.2023 | Reading Time: 3 minutes

This text is machine translated.

NMC rechargeable batteries , or NMC batteries as they are now increasingly being called, belong to the large family of lithium rechargeable batteries. The abbreviation NMC stands for nickel, manganese and cobalt, which is why the batteries are also referred to by experts as lithium-nickel-manganese-cobalt batteries. The name of the rechargeable battery is derived from the material of the positive terminal, for which lithium-nickel-manganese-cobalt oxides are used in different compositions.

Depending on the composition of the oxide, capacity and performance as well as the price can vary greatly. This means that NMC batteries can be optimally configured for the intended application during production by selecting the right electrode material.

The structure of an NMC rechargeable battery corresponds to that of a classic lithium-ion cell with anode, cathode, separator and electrolyte. If required, you can read about the exact structure of a Li-ion cell in our guide to lithium rechargeable batteries.

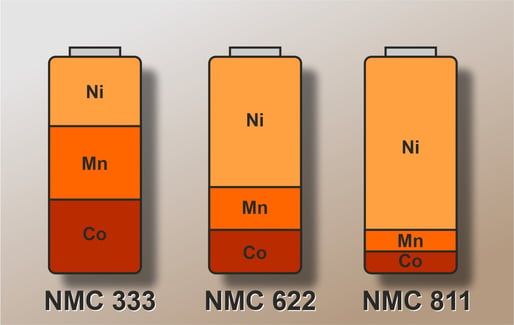

The only difference to the lithium cobalt oxide battery shown in the guide is the structure of the positive electrode. A mixture of lithium nickel manganese cobalt oxide is used for an NMC battery. There are various mixing ratios and technologies for the oxide composition of the electrode:

NMC 333 lithium-ion battery with 33.33% nickel (Ni), 33.33% manganese (Mn) and 33.33% cobalt (Co).

NMC 622 Lithium-ion battery with 60% nickel (Ni), 20% manganese (Mn) and 20% cobalt (Co).

NMC 811 lithium-ion battery with 80% nickel (Ni), 10% manganese (Mn) and 10% cobalt (Co).

Cobalt and cobalt oxides are comparatively expensive. In addition, mining, for example in the Democratic Republic of Congo, is sometimes illegal and does not take social, health, labor or environmental aspects into account. This is why manufacturers are constantly trying to reduce the proportion of cobalt in NMC cells. At the same time, attempts are being made to increase capacity, energy and performance as well as competitiveness.

Just like the design, the way an NMC battery works is identical to other batteries in the lithium-ion series.

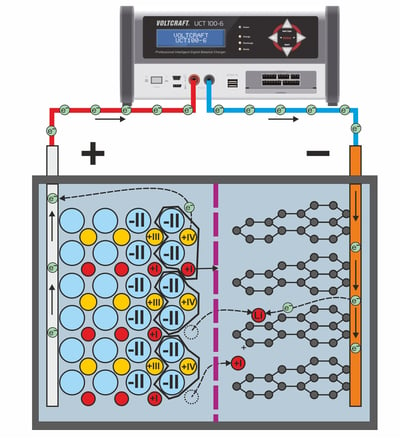

Charging process

During the charging process, the charging voltage removes electrons from the positive electrode of the battery and makes them available at the negative electrode. As a result, lithium ions are released from the positive terminal and migrate through the electrolyte and the separator to the negative terminal. There they each pick up an electron and deposit themselves in the graphite layer . The energy of the charging process thus binds a very high number of electrons to the negative electrode.

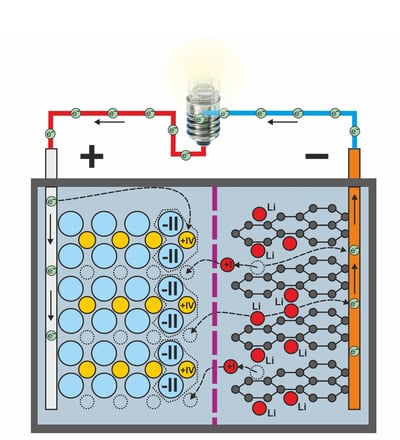

Discharge process

To discharge the battery, it is sufficient to establish an external circuit with a consumer . As soon as the circuit is closed, the lithium releases the previously absorbed electron. It then travels back to the positive electrode as a lithium ion through the separator. The electrons released at the negative electrode also flow via the external circuit to the positive terminal, where they enable the lithium ion to be absorbed into the oxide.

We have described the individual processes that take place during charging and discharging in detail in our guide to lithium batteries.

NMC rechargeable batteries offer very high specific energy and a long service life when used and maintained correctly. This is why these cells are popular and frequently used for a wide variety of applications where performance is of primary importance.

Probably the most important main area of application is electromobility.

Batteries with NMC technology are most frequently used by the automotive industry worldwide in electric cars. Only the US manufacturer Tesla is increasingly relying on NCA batteries or LFP batteries for its electric vehicles.

Even for simple electric vehicles, such as e-bikes or scooters, NMC batteries are the preferred choice.

However, NMC batteries are also increasingly being used in small electronic devices such as smartphones and laptops and have now almost completely replaced the previously used lithium cobalt oxide batteries due to their high energy density.

How can you tell that it is an NMC battery?

Manufacturers often only write Li-Ion on the type plate of the lithium-ion battery and unfortunately do not provide any information regarding the technology used. As the information on the cell voltage is also not helpful in this case, the information must be looked up in the technical documentation for the battery or the respective device if necessary. If in doubt, ask the manufacturer.

What must be observed when handling NMC rechargeable batteries?

When handling rechargeable batteries, the safety instructions specified by the manufacturer should always be observed. This also includes the fact that lithium batteries must always be charged using the charger intended for this purpose. The charging process must always be monitored by the person using the device. When handled properly, lithium batteries are very safe power storage devices with a high energy density and long service life. However, in the event of overcharging or mechanical damage, there is a risk of the battery catching fire. Experts refer to this effect as an exothermic reaction or thermal runaway.

What does the future hold for NMC batteries?

Various companies are working hard to increase performance and service life. Particularly in the field of electromobility, the service life of batteries is a decisive criterion for the purchase of electric vehicles.