TOOLCRAFT soldering stations for industrial use.

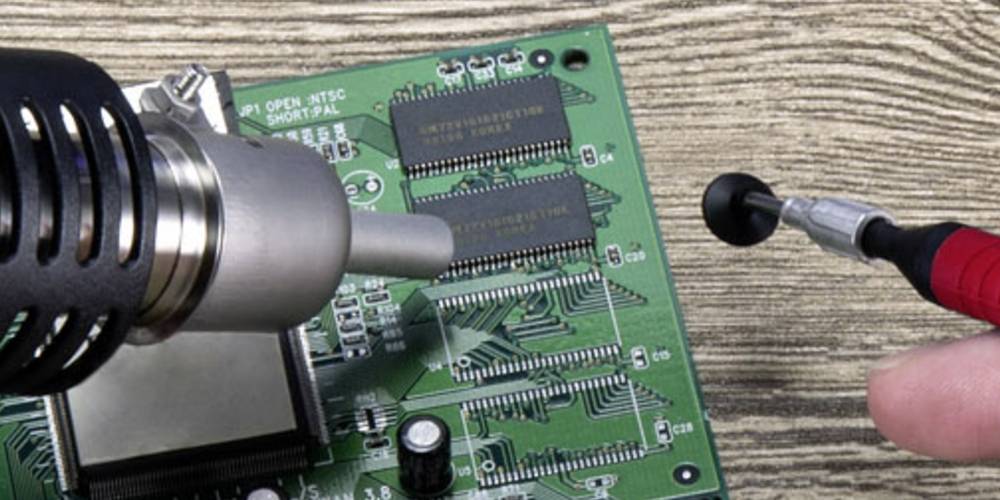

Modern electronic layouts are becoming increasingly minimalist. As a result, the processing of components is becoming increasingly complex. In many cases, component disassembly is no longer possible without hot air. TOOLCRAFT has developed the new TPS-900 rework station to meet these requirements. Hot air, soldering iron, desoldering iron and soldering tweezers are available for simultaneous use. Perfect component placement is made possible by a vacuum pipette. The station has high power reserves and delivers up to 900W when required. This makes the TPS-900 ideal for continuous use.

Removing very small components is no problem with the TPS-800. Various hot air attachments are included in the scope of delivery. This enables optimum adaptation to the component shape and desoldering without damaging the circuit board or damaging neighboring components or desoldering unintentionally is always possible with the TPS-800. The vacuum pipette can also be used to remove or position components with millimeter precision. Various attachments for the vacuum pipette enable even the smallest components to be lifted. TOOLCRAFT underlines the fact that the TPS-800 is a top-class rework station by using a brushless motor to generate the air flow for the hot air.

Soldering stations for cable assembly and use in service.

TOOLCRAFT ST-200 Pro 230W

TOOLCRAFT ST-150 HF high-frequency soldering station 150W

Lead-free solder

| Item-No. | Alloy | Flux | Diameter | Weight | Melting point | Flux content % | Halogen content % |

| 2160419 | Sn99,3Cu0,7 | ROL1 | 0.5 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160420 | Sn99,3Cu0,7 | ROL1 | 0.5 mm | 250 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160421 | Sn99,3Cu0,7 | ROL1 | 1 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160422 | Sn99,3Cu0,7 | ROL1 | 1 mm | 250 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160423 | Sn99,3Cu0,7 | ROL1 | 1 mm | 500 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160424 | Sn99,3Cu0,7 | ROL1 | 1.5 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160425 | Sn99,3Cu0,7 | ROL1 | 1.5 mm | 250 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2160426 | Sn99,3Cu0,7 | ROL1 | 1.5 mm | 500 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2481259 | Sn99,3Cu0,7 | ROL1 | 0.3 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2481260 | Sn99,3Cu0,7 | ROL1 | 0.7 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2481261 | Sn99,3Cu0,7 | ROL1 | 1.2 mm | 100 g | 227-228°C | 3.0 ± 1.0% | <0.5% |

| 2490630 | SN99AG03C | ROL1 | 0.5 mm | 100 g | 217-226°C | 3.0 ± 1.0% | <0.5% |

| 2490631 | SN99AG03C | ROL1 | 1 mm | 100 g | 217-226°C | 3.0 ± 1.0% | <0.5% |

| 2490632 | SN99AG03C | ROL1 | 1.5 mm | 100 g | 217-226°C | 3.0 ± 1.0% | <0.5% |

| 2481256 | Sn96,5Ag3Cu0,5 | ROL1 | 0.5 mm | 100 g | 217-219°C | 3.0 ± 1.0% | <0.5% |

| 2481257 | Sn96,5Ag3Cu0,5 | ROL1 | 0.7 mm | 100 g | 217-219°C | 3.0 ± 1.0% | <0.5% |

| 2481258 | Sn96,5Ag3Cu0,5 | ROL1 | 1 mm | 100 g | 217-219°C | 3.0 ± 1.0% | <0.5% |

| 2490629 | Sn96,5Ag3Cu0,5 | ROL1 | 1.5 mm | 100 g | 217-219°C | 3.0 ± 1.0% | <0.5% |